Our Services

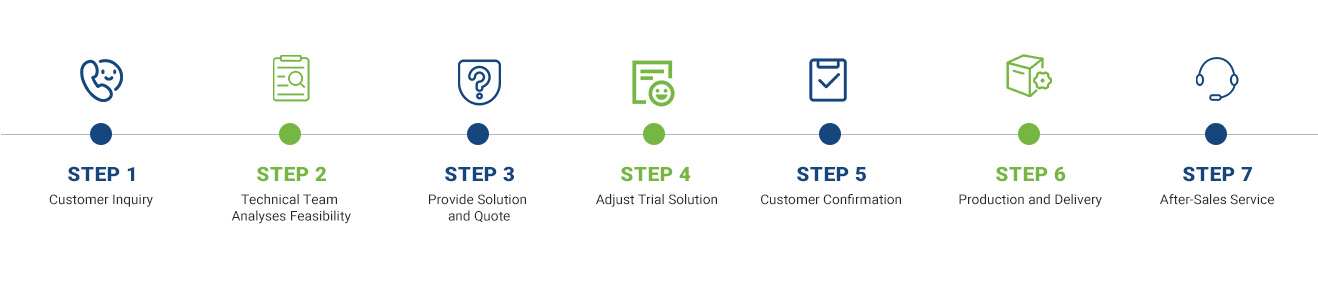

We specialize in delivering comprehensive, customized solutions tailored to our clients' unique requirements. Our services encompass production line design, equipment upgrades, and product parameter adjustments based on trial results, ensuring optimal performance and feasibility. Our team consists of experts with deep theoretical knowledge and extensive practical experience in binder engineering R&D, design, manufacturing, and technical support. We offer a full range of services, including technical consultation, scheme design, product fabrication, equipment sourcing, installation and commissioning, binder supply, production operations, and dedicated after-sales support. Additionally, we provide turnkey EPC (Engineering, Procurement, and Construction) services or phased EPC solutions, customized to meet our clients' specific requirements.

Service Process

Industries We Serve

Specialized in metallurgical slag, coal coking, briquetting, mining and iron ore pellets binder.